Frame repair techniques require thorough assessment of damage, ranging from dents to misalignment, using advanced tools like laser measuring systems and 3D scanners. These technologies ensure accurate restoration of structural integrity and aesthetic appeal, guaranteeing vehicle safety, reliability, and longevity. Modern alignment systems offer collision repair shops unprecedented precision, crucial for complex scenarios and maintaining high-quality standards. Skilled technicians use these tools to precisely align components, maintain clean workspaces, and adhere to manufacturer guidelines for optimal outcomes in auto body shops.

Frame repair techniques are essential for restoring structural integrity in vehicles. This article delves into two critical aspects of modern frame repair: measuring accuracy and advanced alignment systems. By understanding various types of frame damage and implementing precise measurement methods, technicians can ensure accurate repairs. Advanced alignment tools play a pivotal role in achieving perfect results, ensuring the vehicle’s safety and performance. Additionally, best practices and tips are shared to guide professionals through effective frame repair processes.

- Understanding Frame Damage and Measuring Accuracy

- Advanced Alignment Systems for Precise Repairs

- Best Practices and Tips for Effective Frame Repair

Understanding Frame Damage and Measuring Accuracy

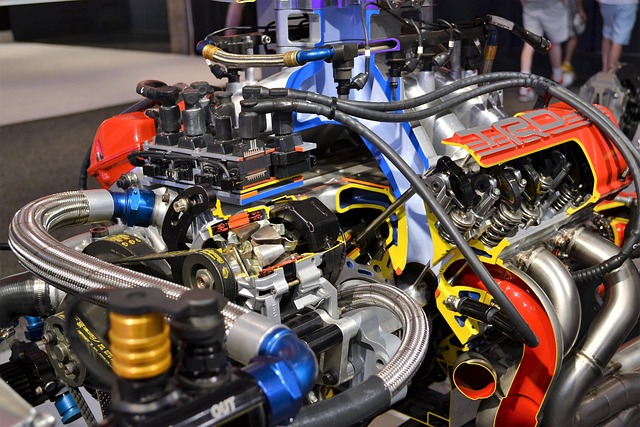

Understanding Frame Damage is a critical step before employing any frame repair techniques. Auto body shops need to meticulously assess the extent of damage, which can vary greatly from minor dents and dings to severe crumpling or misalignment. Accurately identifying these issues involves skilled technicians who utilize specialized tools to measure and visualize the frame’s integrity. This process ensures that every repair is tailored to the specific needs of the vehicle, whether it’s a simple straightening job or complex reconstruction after an accident.

Measuring accuracy is paramount in frame repair techniques because even minor inaccuracies can lead to long-term structural issues. Professionals rely on advanced technologies and meticulous techniques like laser measuring systems and 3D scanning to ensure precise alignment of the frame components. These car repair services not only guarantee the safety and reliability of the vehicle but also help maintain its aesthetic appeal, especially in intricate vehicle paint repair processes that follow.

Advanced Alignment Systems for Precise Repairs

In modern frame repair techniques, advanced alignment systems have become indispensable tools for achieving precise and accurate repairs. These cutting-edge technologies offer collision repair shops unparalleled precision when realigning vehicle frames after accidents or damage. By utilizing sophisticated sensors and computer-aided measurement devices, these systems can detect even the most subtle misalignments, ensuring that the frame is restored to its original specifications. This level of accuracy is crucial in preserving the structural integrity and overall safety of vehicles, especially in complex automotive collision repair scenarios.

One notable advantage of advanced alignment systems is their ability to streamline the paintless dent repair process. By precisely measuring and adjusting panel gaps, these systems help technicians achieve seamless results without the need for extensive body work or repainting. This not only reduces labor costs but also minimizes the environmental impact associated with traditional automotive collision repair methods. As a result, many collision repair shops are adopting these innovative frame repair techniques to stay competitive in the market while maintaining high-quality standards.

Best Practices and Tips for Effective Frame Repair

When undertaking frame repair techniques, whether for a car, motorcycle or other vehicle, adhering to best practices is paramount. The first step in any successful frame repair involves thorough inspection and accurate measurement. This includes identifying the extent of damage, assessing the structural integrity of the frame, and taking precise dimensions to ensure exact replacement or adjustments. Utilizing advanced measuring tools such as laser scanners and digital calipers enhances accuracy, which is crucial for aligning components correctly during the repair process.

Effective alignment systems play a pivotal role in frame repair techniques. Once measurements are taken, specialized equipment aligns the frame components to their pre-damage positions. This meticulous process requires skill and experience to avoid further damage or misalignment. Maintaining a clean and organized work area, using high-quality tools and materials, and adhering to manufacturer guidelines for car paint services and vehicle restoration, all contribute to ensuring the best outcomes in auto repair shops.

In conclusion, mastering frame repair techniques hinges on understanding damage assessment, utilizing advanced alignment systems, and adhering to best practices. By ensuring precise measuring and careful alignment, professionals can achieve optimal results in frame repairs, restoring vehicles to their pre-accident condition. These techniques are essential components of the automotive industry’s commitment to effective and efficient frame repair solutions.